Capacitors are fundamental components in electrical engineering, serving as passive devices that store and release electrical energy. They consist of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field develops, allowing the capacitor to store energy in the form of an electrostatic charge.

The ability of a capacitor to store charge is quantified by its capacitance, measured in farads (F). This property makes capacitors essential in various applications, from smoothing out voltage fluctuations in power supplies to filtering signals in audio equipment. The functions of capacitors extend beyond mere energy storage.

They play a crucial role in timing applications, where they can be used in conjunction with resistors to create time delays in circuits. In oscillators, capacitors help generate specific frequencies by charging and discharging at controlled rates. Additionally, capacitors are integral to coupling and decoupling signals in electronic circuits, allowing for the transmission of alternating current (AC) while blocking direct current (DC).

Key Takeaways

- Capacitors store and release electrical energy, acting as a temporary power source and helping to stabilize voltage in electrical circuits.

- When choosing a capacitor for your application, consider factors such as voltage rating, capacitance value, and temperature stability to ensure optimal performance.

- Proper installation and maintenance of capacitors is crucial for their longevity and efficiency, including ensuring correct polarity, avoiding overvoltage, and regular inspection for signs of wear or damage.

- Capacitors can be used for power factor correction to improve energy efficiency and reduce electricity costs in industrial and commercial settings.

- In motor control and start-up applications, capacitors can help improve the efficiency and performance of electric motors, reducing energy consumption and extending motor life.

Choosing the Right Capacitor for Your Application

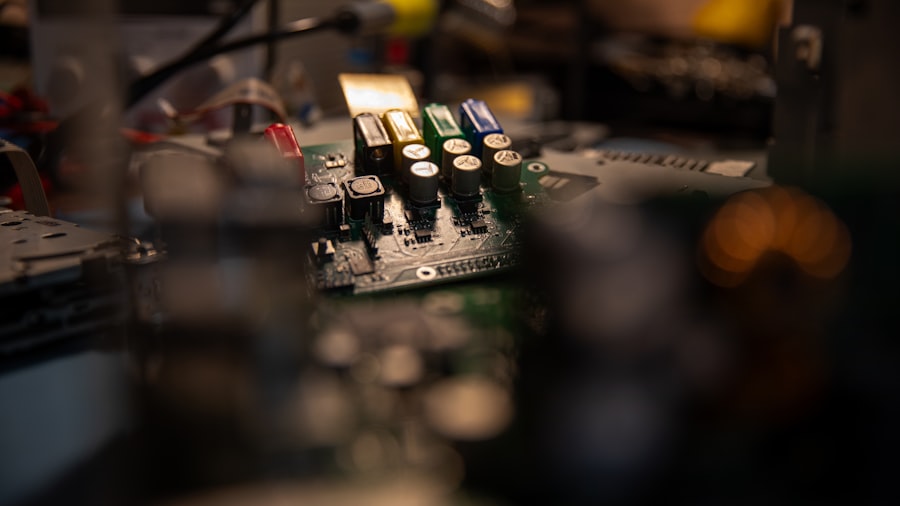

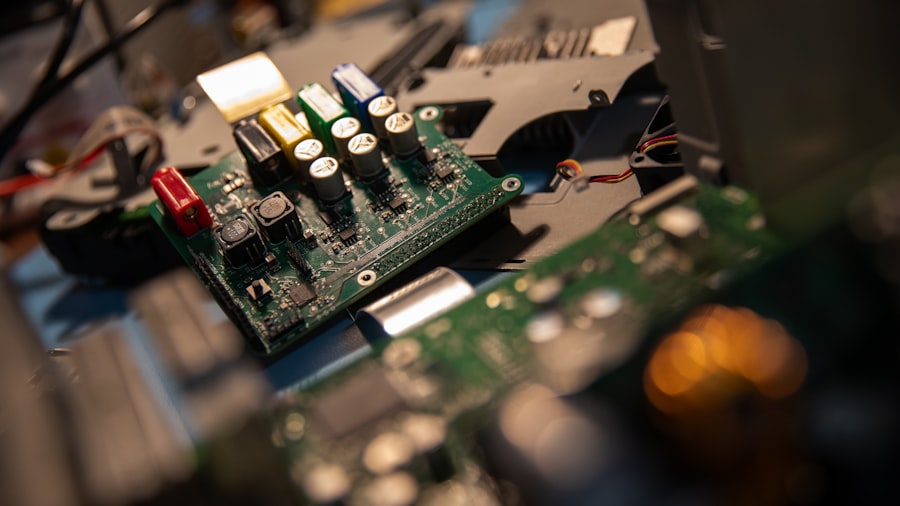

Capacitor Types and Their Properties

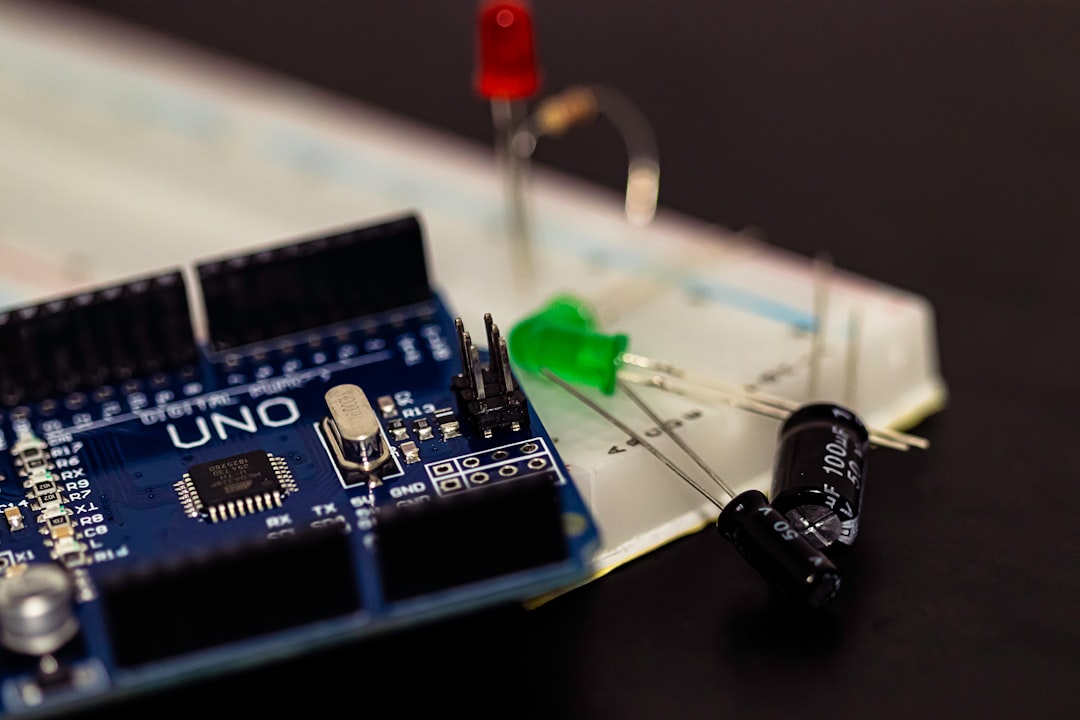

For instance, ceramic capacitors are often favored for high-frequency applications due to their low equivalent series resistance (ESR) and stability over temperature variations. On the other hand, electrolytic capacitors are typically used in power supply circuits because of their high capacitance values, which allow them to store significant amounts of energy.

Key Factors to Consider When Choosing a Capacitor

When choosing a capacitor, it is essential to consider factors such as voltage rating, capacitance value, temperature coefficient, and physical size. The voltage rating indicates the maximum voltage the capacitor can handle without risk of breakdown, while the capacitance value determines how much charge it can store.

Ensuring Reliable Performance

Additionally, the temperature coefficient affects performance under varying thermal conditions; for example, tantalum capacitors are known for their stability across a wide temperature range but can be more expensive than other options. Understanding these parameters ensures that the selected capacitor will perform reliably within its intended application.

Proper Installation and Maintenance of Capacitors

The installation and maintenance of capacitors are critical to ensuring their longevity and optimal performance. Proper installation begins with adhering to the manufacturer’s specifications regarding orientation and mounting. For instance, electrolytic capacitors are polarized and must be installed with the correct polarity; failure to do so can lead to catastrophic failure, including leakage or explosion.

Additionally, ensuring that the capacitor is securely mounted can prevent mechanical stress that may arise from vibrations or thermal expansion. Regular maintenance is equally important for capacitors, particularly in industrial settings where they may be subjected to harsh conditions. Periodic inspections should include checking for signs of physical damage, such as bulging or corrosion, which can indicate impending failure.

Furthermore, measuring capacitance and ESR can provide insights into the health of the capacitor; significant deviations from expected values may warrant replacement. Implementing a proactive maintenance schedule not only extends the life of capacitors but also enhances overall system reliability.

Utilizing Capacitors for Power Factor Correction

| Capacitor Size | Power Factor Improvement | Energy Savings |

|---|---|---|

| 10 kVAR | 0.05 | 5% |

| 20 kVAR | 0.1 | 10% |

| 50 kVAR | 0.25 | 25% |

Power factor correction (PFC) is a critical aspect of electrical systems that can significantly enhance efficiency and reduce energy costs.

A low power factor indicates that a significant portion of the power is reactive rather than productive, often due to inductive loads such as motors and transformers.

Capacitors can be employed to counteract this effect by providing leading reactive power, thus improving the overall power factor. In practical applications, capacitor banks are often installed alongside inductive loads to balance the reactive power demand. By strategically placing these banks within an electrical system, businesses can reduce their demand charges and avoid penalties associated with low power factors.

For example, a manufacturing facility with large motors may experience significant savings on its electricity bill by implementing PFC strategies using capacitors. Moreover, improving the power factor can lead to reduced losses in transmission lines and enhanced capacity for additional loads without necessitating upgrades to existing infrastructure.

Capacitors in Motor Control and Start-Up Applications

Capacitors play a pivotal role in motor control applications, particularly during start-up phases where high initial torque is required. In single-phase induction motors, start capacitors are employed to create a phase shift that generates a rotating magnetic field necessary for initiating motor rotation. These capacitors are typically designed for short-term use and are disconnected from the circuit once the motor reaches a certain speed.

The proper selection of start capacitors is crucial; using one with insufficient capacitance can result in inadequate starting torque, while an oversized capacitor may lead to overheating and premature failure. In addition to start capacitors, run capacitors are utilized in both single-phase and three-phase motors to improve efficiency during operation. These capacitors remain connected throughout the motor’s running cycle and help maintain a more consistent torque output while reducing energy consumption.

The integration of run capacitors can lead to smoother operation and extended motor life by minimizing electrical stress on windings. Understanding the specific requirements of motor applications allows engineers to select appropriate capacitors that enhance performance and reliability.

Improving Efficiency with Capacitor Banks

Energy Cost Savings

The deployment of capacitor banks can lead to significant reductions in energy costs by minimizing losses associated with low power factors.

Design and Configuration

The design and configuration of capacitor banks depend on several factors, including load characteristics and system requirements. For instance, fixed capacitor banks provide constant reactive power compensation but may not adapt well to fluctuating loads.

Automatic Capacitor Banks

Conversely, automatic capacitor banks utilize control systems to adjust capacitance dynamically based on real-time load conditions. This adaptability ensures optimal performance across varying operational scenarios, maximizing energy savings while maintaining system stability.

Integrating Capacitors into Renewable Energy Systems

As renewable energy sources such as solar and wind become increasingly prevalent, the integration of capacitors into these systems has gained importance. Capacitors serve multiple functions within renewable energy applications, including energy storage, voltage regulation, and smoothing out fluctuations caused by intermittent generation. In solar photovoltaic (PV) systems, capacitors can help manage rapid changes in output due to varying sunlight conditions, ensuring a stable supply of electricity to the grid or local loads.

In wind energy systems, capacitors play a vital role in maintaining grid stability by providing reactive power support during periods of high demand or low generation. The ability to quickly respond to changes in load conditions makes capacitors essential for enhancing the reliability of renewable energy systems. Furthermore, advancements in capacitor technology have led to the development of supercapacitors, which offer high energy density and rapid charge/discharge capabilities—ideal for applications requiring quick bursts of power or energy storage solutions that complement traditional battery systems.

Best Practices for Maximizing Efficiency with Capacitors

To maximize efficiency when utilizing capacitors in various applications, several best practices should be followed. First and foremost is ensuring proper sizing based on load requirements; undersized capacitors may lead to inadequate performance while oversized units can introduce unnecessary costs and potential reliability issues. Conducting thorough load analysis helps determine the optimal capacitance values needed for specific applications.

Additionally, regular monitoring and maintenance are essential for sustaining capacitor performance over time. Implementing condition monitoring systems that track parameters such as voltage, current, temperature, and capacitance can provide valuable insights into operational health. This proactive approach allows for timely interventions before failures occur, ultimately enhancing system reliability and efficiency.

Moreover, educating personnel on capacitor technology and its implications within their specific context fosters a culture of awareness that can lead to better decision-making regarding installation and maintenance practices. By adhering to these best practices, organizations can ensure that their use of capacitors contributes positively to overall system performance while minimizing costs associated with energy consumption and equipment failures.

If you are interested in learning more about the fascinating world of fractals, I recommend checking out this article on exploring fractals: the Julia set and the Mandelbrot set. Fractals are complex and beautiful mathematical patterns that can be found in nature and art. Understanding their intricate structures can provide valuable insights into the world around us.

+ There are no comments

Add yours