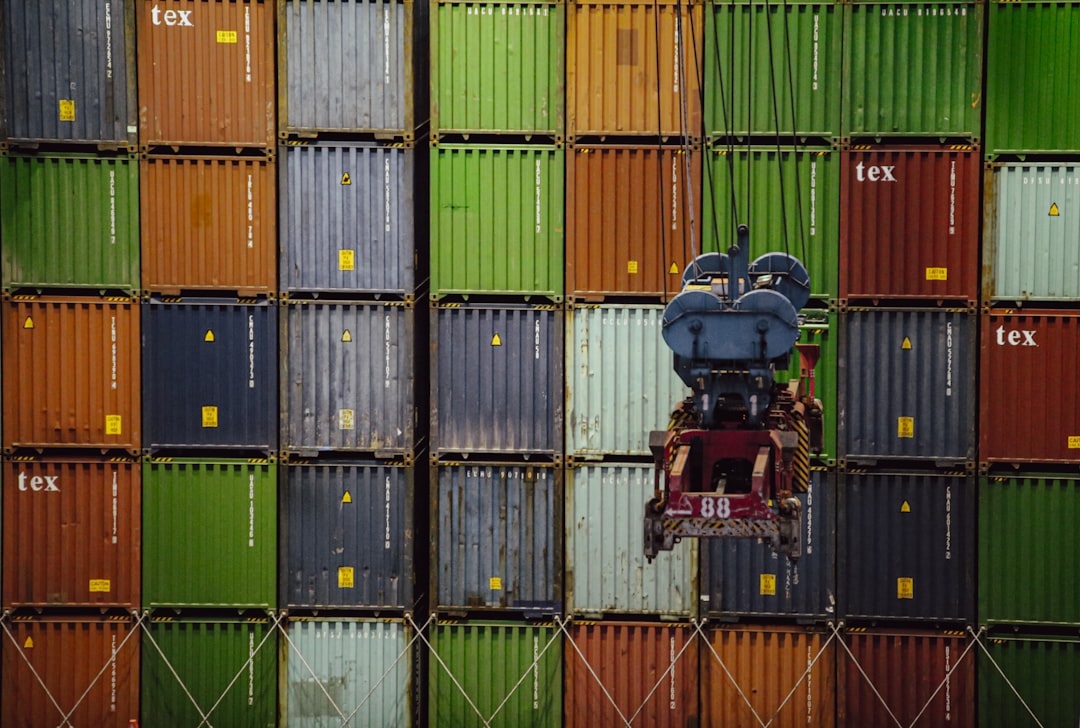

The concept of containerization, which revolutionized the shipping industry, can be traced back to the mid-20th century. The pivotal moment came in 1956 when Malcolm McLean, an American trucking entrepreneur, introduced the first modern shipping container. McLean’s vision was to streamline the process of loading and unloading cargo ships, which at the time was labor-intensive and time-consuming.

He designed a standardized metal box that could be easily transferred between ships, trucks, and trains, thus eliminating the need for manual handling of individual items.

The adoption of containerization was not instantaneous; it required significant investment in infrastructure and technology.

Ports around the world had to adapt to accommodate container ships and the new loading and unloading techniques. The first container ship, the Ideal X, made its maiden voyage from Newark to Houston, carrying 58 containers. This initial success demonstrated the potential of containerization, leading to a rapid expansion of container shipping services.

By the 1970s, major shipping lines began to invest heavily in container fleets, and ports started to develop specialized container terminals. The standardization of container sizes—most notably the 20-foot and 40-foot containers—further facilitated this growth, allowing for efficient stacking and storage.

Key Takeaways

- Containerization revolutionized global trade by standardizing the shipping process and reducing costs

- Technology plays a crucial role in containerization, from tracking systems to automated ports

- Advantages of containerization include increased efficiency and security, while disadvantages include potential job displacement

- Containerization has a significant environmental impact, with concerns about emissions and waste

- The future of containerization includes innovations in sustainability and automation, shaping the future of supply chain management

The Impact of Containerization on Global Trade

Containerization has had a profound impact on global trade dynamics, fundamentally altering how goods are transported across borders. One of the most significant effects has been the dramatic reduction in shipping costs. Prior to containerization, transporting goods was a labor-intensive process that involved multiple handling stages, each adding to the overall cost.

With containers, goods could be loaded directly onto ships with minimal handling, resulting in lower labor costs and faster turnaround times. This efficiency has made international trade more accessible to businesses of all sizes, enabling small and medium enterprises to participate in global markets. Moreover, containerization has facilitated the globalization of supply chains.

Companies can now source materials from different parts of the world and assemble products in locations that offer cost advantages. For instance, a smartphone might be designed in California, components manufactured in South Korea and Japan, assembled in China, and then shipped to consumers worldwide—all thanks to the efficiency of containerized shipping. This interconnectedness has led to increased competition and innovation as businesses strive to optimize their supply chains and reduce costs.

The ability to transport goods quickly and reliably has also contributed to the rise of just-in-time inventory systems, where companies keep minimal stock on hand and rely on frequent shipments to meet demand.

The Role of Technology in Containerization

Technology has played a crucial role in the evolution of containerization, enhancing its efficiency and effectiveness. The introduction of computerized tracking systems has transformed how containers are monitored throughout their journey. Each container is equipped with a unique identification number that allows it to be tracked in real-time via GPS and RFID technology.

This capability not only improves visibility for shipping companies but also enhances security by reducing the risk of theft or loss during transit. In addition to tracking technologies, advancements in automation have further streamlined operations at ports and warehouses. Automated cranes and robotic systems are increasingly being used to load and unload containers, reducing reliance on manual labor and increasing throughput.

For example, the Port of Rotterdam has implemented automated guided vehicles (AGVs) that transport containers between terminals without human intervention. These innovations not only speed up operations but also minimize human error, leading to safer and more efficient port environments.

Advantages and Disadvantages of Containerization

| Advantages of Containerization | Disadvantages of Containerization |

|---|---|

| Isolation: Containers provide a high level of isolation for applications and their dependencies. | Complexity: Managing a large number of containers can become complex and require additional tools. |

| Portability: Containers can be easily moved between environments, making them highly portable. | Security: Containers can introduce security risks if not properly configured and managed. |

| Resource Efficiency: Containers consume fewer resources compared to traditional virtual machines. | Learning Curve: Adopting containerization may require a learning curve for development and operations teams. |

| Scalability: Containers can be quickly scaled up or down based on demand, improving resource utilization. | Networking: Container networking can be complex and may require additional configuration for communication between containers. |

Containerization offers numerous advantages that have made it the preferred method for transporting goods globally. One of the most notable benefits is cost efficiency. By standardizing cargo transport, shipping companies can maximize space utilization on vessels, leading to lower per-unit shipping costs.

This efficiency translates into lower prices for consumers as businesses can pass on savings from reduced shipping expenses. However, containerization is not without its drawbacks. One significant disadvantage is the environmental impact associated with increased shipping activity.

Additionally, larger ships require deeper ports and more extensive infrastructure, which can disrupt local ecosystems and communities. The concentration of shipping activities in major ports can also lead to congestion and increased traffic in surrounding areas, raising concerns about urban planning and sustainability.

Environmental Impact of Containerization

The environmental implications of containerization are multifaceted and warrant careful consideration. On one hand, containerization has enabled more efficient transportation of goods over long distances, which can reduce the carbon footprint per unit of cargo compared to traditional shipping methods. However, the sheer volume of containers being transported globally has led to significant environmental challenges.

One major concern is greenhouse gas emissions from container ships. These vessels are often powered by heavy fuel oil, which emits high levels of carbon dioxide (CO2) and other pollutants into the atmosphere. According to estimates from the International Maritime Organization (IMO), international shipping accounts for approximately 2-3% of global CO2 emissions.

As global trade continues to expand, so too does the environmental impact associated with it. Efforts are underway to mitigate these effects through regulations aimed at reducing emissions and promoting cleaner fuels. Another environmental issue linked to containerization is marine pollution caused by shipping activities.

Oil spills, ballast water discharge containing invasive species, and plastic waste from containers can have devastating effects on marine ecosystems. The increasing size of container ships also raises concerns about their potential for accidents or grounding incidents that could lead to catastrophic environmental damage.

The Future of Containerization

Sustainability in Shipping

As awareness of climate change grows, the shipping industry is under increasing pressure to adopt greener practices. This includes investing in alternative fuels such as liquefied natural gas (LNG) or hydrogen, as well as exploring electric propulsion systems for smaller vessels.

Digital Transformation in Logistics

Digital transformation will continue to play a significant role in shaping the future of containerization. The integration of artificial intelligence (AI) and machine learning into logistics operations can enhance predictive analytics for demand forecasting and inventory management. Additionally, blockchain technology is being explored as a means to improve transparency and traceability within supply chains, reducing fraud and enhancing security.

Geopolitical Factors and Regional Supply Chains

Geopolitical factors may also influence the future landscape of containerization. Trade tensions between major economies can lead to shifts in trade routes and supply chain strategies as companies seek to mitigate risks associated with tariffs or political instability. As businesses adapt to these changes, they may increasingly rely on regional supply chains rather than global ones, potentially altering the dynamics of containerized shipping.

Innovations in Containerization

Innovation within the realm of containerization is ongoing and multifaceted, driven by both technological advancements and evolving market demands. One notable area of innovation is the development of smart containers equipped with sensors that monitor conditions such as temperature, humidity, and shock during transit. These smart containers provide real-time data that can help shippers ensure that sensitive cargo—such as pharmaceuticals or perishable goods—arrives at its destination in optimal condition.

Another significant innovation is the use of modular containers that can be easily reconfigured for different types of cargo or transportation modes. These versatile containers allow for greater flexibility in logistics operations, enabling companies to adapt quickly to changing market conditions or customer needs. For instance, a modular container could be used for both dry goods and refrigerated items by simply adjusting its internal configuration.

Moreover, advancements in materials science are leading to the creation of lighter yet stronger containers that can withstand harsh marine environments while reducing fuel consumption during transport. Innovations such as composite materials or advanced coatings can enhance durability while minimizing weight—a critical factor for maximizing cargo capacity on vessels.

Containerization and Supply Chain Management

Containerization has fundamentally transformed supply chain management by introducing new levels of efficiency and complexity into logistics operations. The ability to move large volumes of goods quickly across vast distances has enabled companies to optimize their supply chains like never before. With standardized containers facilitating seamless transfers between different modes of transport—such as ships, trucks, and trains—businesses can achieve greater agility in responding to market demands.

One key aspect of effective supply chain management in a containerized world is inventory optimization. Companies can leverage data analytics tools to monitor inventory levels across various locations in real-time, allowing them to make informed decisions about when and where to replenish stock. This capability is particularly valuable in industries with fluctuating demand patterns or seasonal variations.

Furthermore, collaboration among stakeholders within the supply chain has become increasingly important due to the interconnected nature of containerized logistics. Shippers must work closely with port authorities, freight forwarders, customs officials, and other partners to ensure smooth operations throughout the entire supply chain process. Effective communication and information sharing are essential for minimizing delays and maximizing efficiency.

In conclusion, while containerization has brought about remarkable advancements in global trade and logistics management, it also presents challenges that require ongoing attention from industry stakeholders. As technology continues to evolve and environmental concerns grow more pressing, the future landscape of containerization will undoubtedly be shaped by innovation and collaboration across all sectors involved in this vital aspect of international commerce.

If you are interested in exploring the intersection of mathematics education, history, and culture, you may find the article Exploring the Intersection of Mathematics Education, History, and Culture to be a fascinating read. This article delves into how mathematics has been taught throughout history and how cultural influences have shaped the way we approach math education today. It provides valuable insights into the importance of understanding the cultural context in which mathematical concepts are taught.

+ There are no comments

Add yours